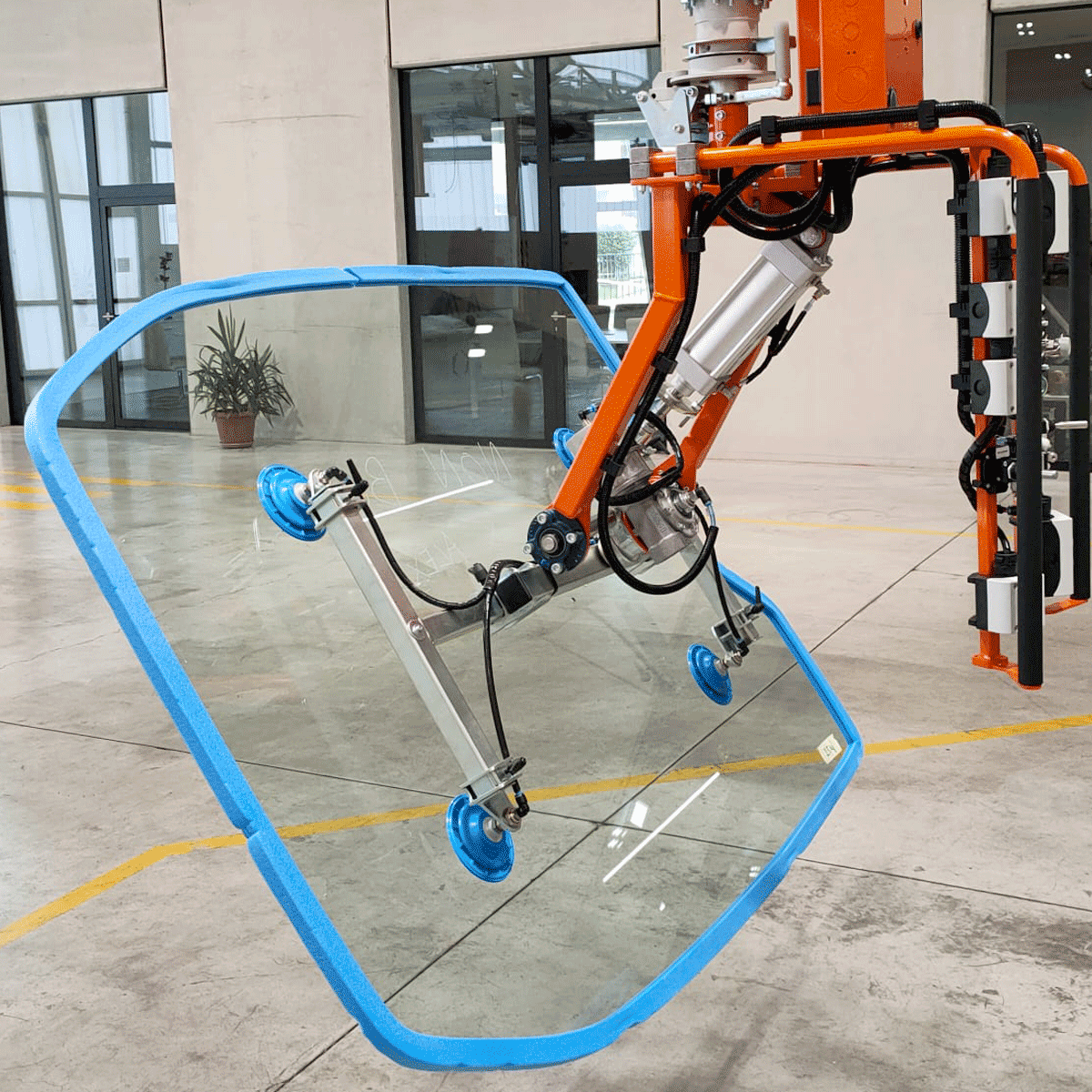

ATIS is a responsive and flexible company, capable of meeting the specific handling needs of each customer through technologically advanced solutions.

Each ATIS pneumatic manipulator is custom-designed, starting from direct dialogue with the customer and continuing through constant collaboration in every phase — from the design of the gripping system to the final delivery of the product.