Handling drums across different industrial sectors requires solutions that balance safety, efficiency, and costs. While forklifts, manual carts, or manual drum lifters offer alternatives for transporting loads, ATIS industrial manipulators emerge as the most advanced solution for precise and safe operations.

Contact us now

Fields marked with * are mandatory.

Solutions

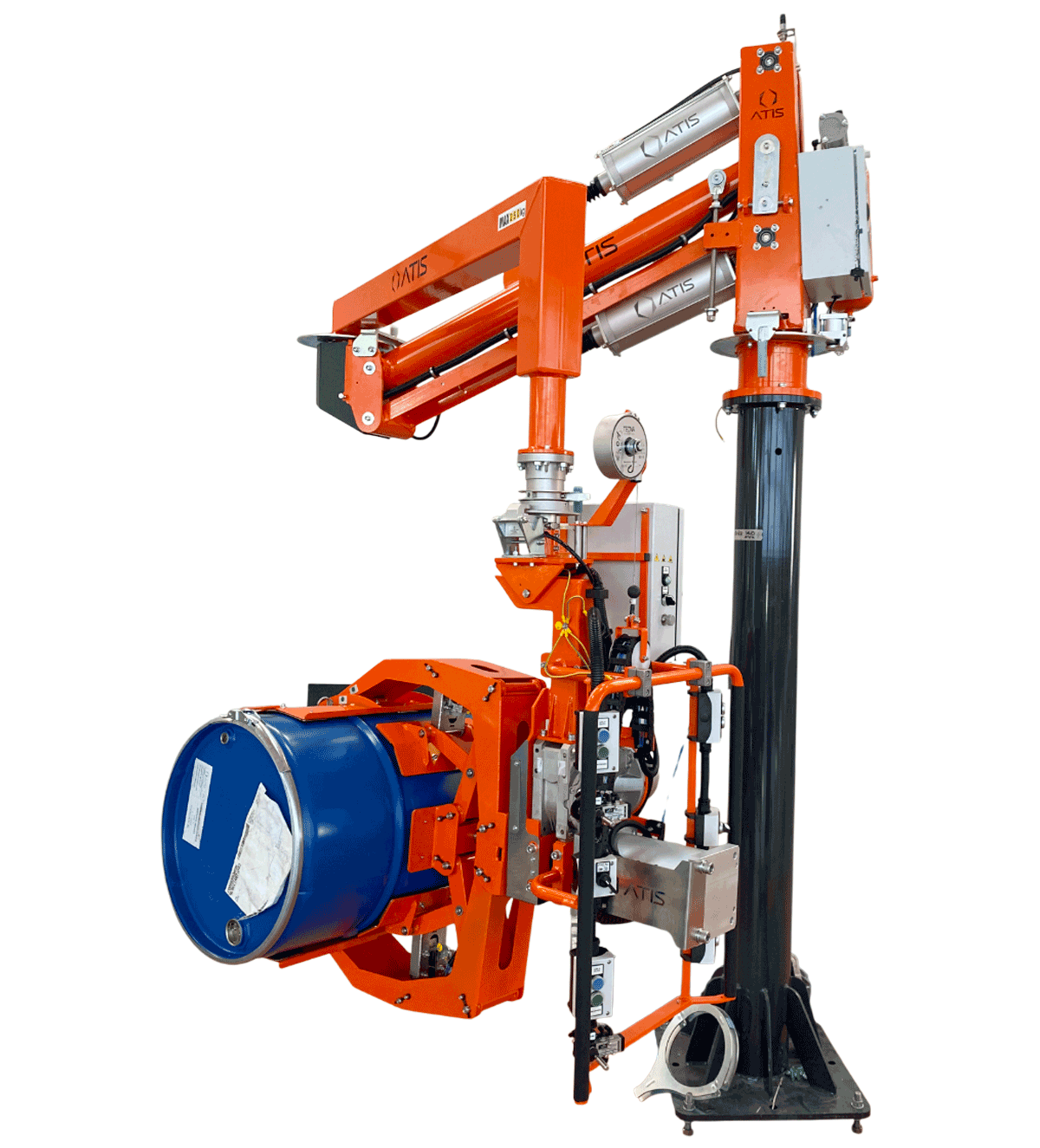

Handling Drums with Lifting and Rotation

Chemical, Drums

Comparison Between Manipulators and Manual Drum Lifters in Drum Handling

ATIS Industrial Manipulators

Advantages:

- Fast and precise movements, optimizing handling times even with drums weighing over 600 kg.

- Precise movement control, ensuring both safety and delicacy.

- Customized gripping tools designed to adapt to different types of drums and handling requirements.

- Reduction of long‑term operating costs, thanks to fewer damages, fewer injuries, reduced downtime, and the high reliability of ATIS manipulators.

- Versatility and flexibility, with the ability to work in confined spaces and perform complex operations.

Efficiency:

- ATIS manipulators are designed to operate even in tight spaces and to perform complex tasks, such as rotating and tilting drums while emptying their contents—even liquids—and they can also indicate the quantity of product poured.

- They are ideal for operations requiring high precision and offer ergonomics unmatched by any other drum‑handling system.

Manual Drum Lifters: An Alternative with Limitations

Manual drum lifters represent an intermediate solution between manual carts and industrial manipulators. They provide mechanical assistance for lifting, but they present significant limitations in terms of ergonomics, precision, and versatility.

Features and Operation

Mechanical Assistance:

- Manual drum lifters use hydraulic or screw mechanisms to facilitate the lifting of drums.

- They reduce physical effort compared to fully manual lifting.

Limited Mobility:

- They are designed for short-distance movements on flat surfaces.

- Handling in confined spaces can be challenging.

Manual Control:

- Gripping, lifting, and positioning operations are controlled manually by the operator.

- Precision depends on the operator’s skill and physical strength.

In summary

Manual drum lifters represent an intermediate solution that provides an improvement over basic manual carts, but they do not reach the level of efficiency, safety, and ergonomics offered by industrial manipulators. Although they may reduce physical effort compared to fully manual lifting, the risk of fatigue and injuries remains, especially during repetitive operations.

Precision—crucial for the delicate handling of drums—is lower in manual lifters, as it depends on the operator’s skill, increasing the risk of damage to the drums and to the surrounding environment. Versatility is limited by the design of the lifter and by the need for manual control, making tilting and rotating operations difficult or even impossible.

From a cost perspective, although the initial investment in manual drum lifters is lower compared to manipulators, long‑term operating costs can be high due to injuries and material damage. Productivity is also limited when compared to manipulators, which offer fast, precise, and customizable movements.

Therefore, the choice of drum‑handling solution depends on the specific needs of the application. For simple and occasional tasks, manual lifters may be sufficient. However, ATIS industrial manipulators represent the most efficient, safe, and ergonomic option for drum handling, ensuring long‑term reductions in operating costs and a significant increase in productivity, with a rapid return on the initial investment.

Choosing the right drum‑handling solution depends on the specific needs of the application, and factors such as frequency, weight, precision, and ergonomics must always be taken into account.

Let’s design your handling solution together.

Safe. Ergonomic. Tailor-made.