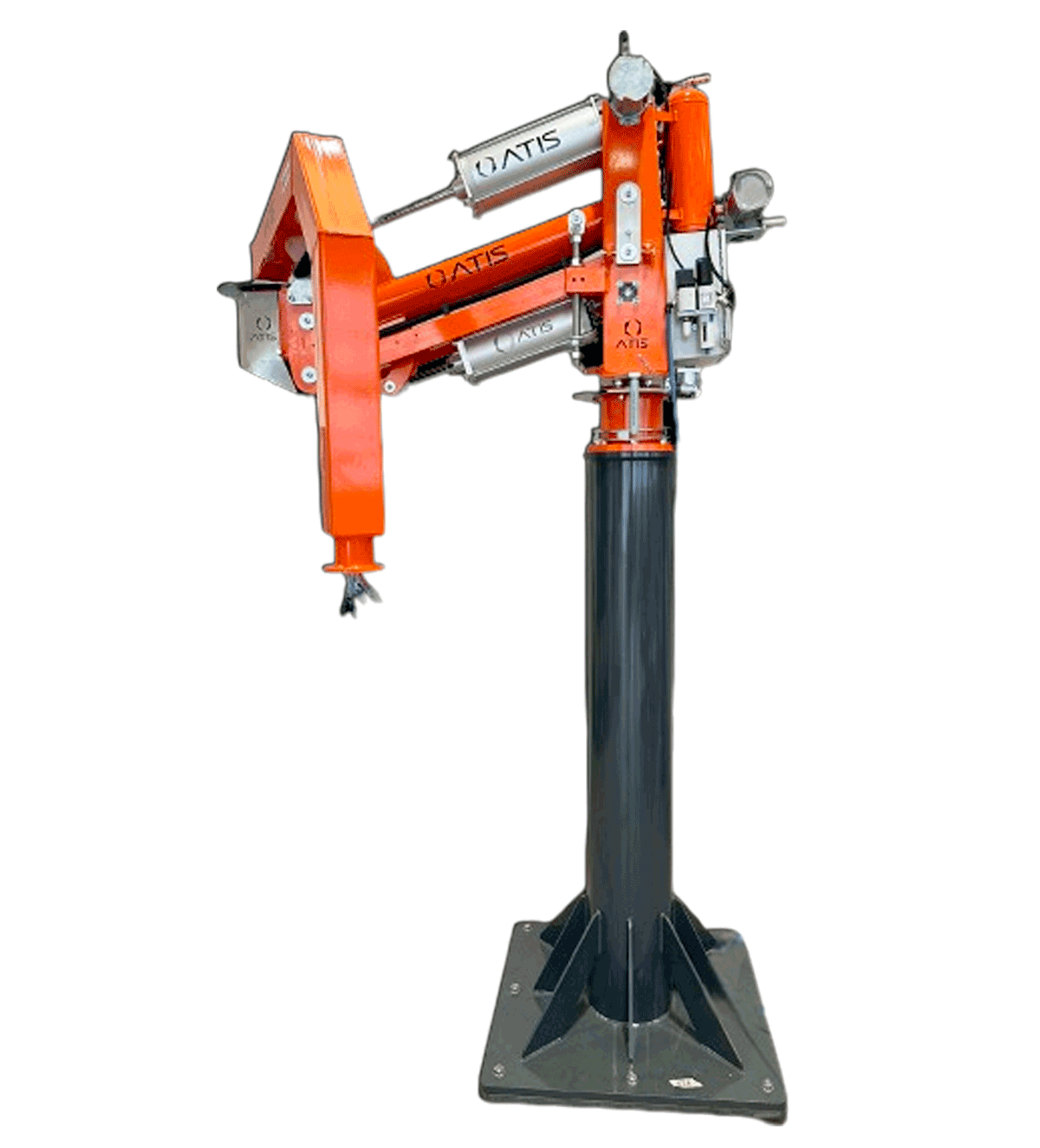

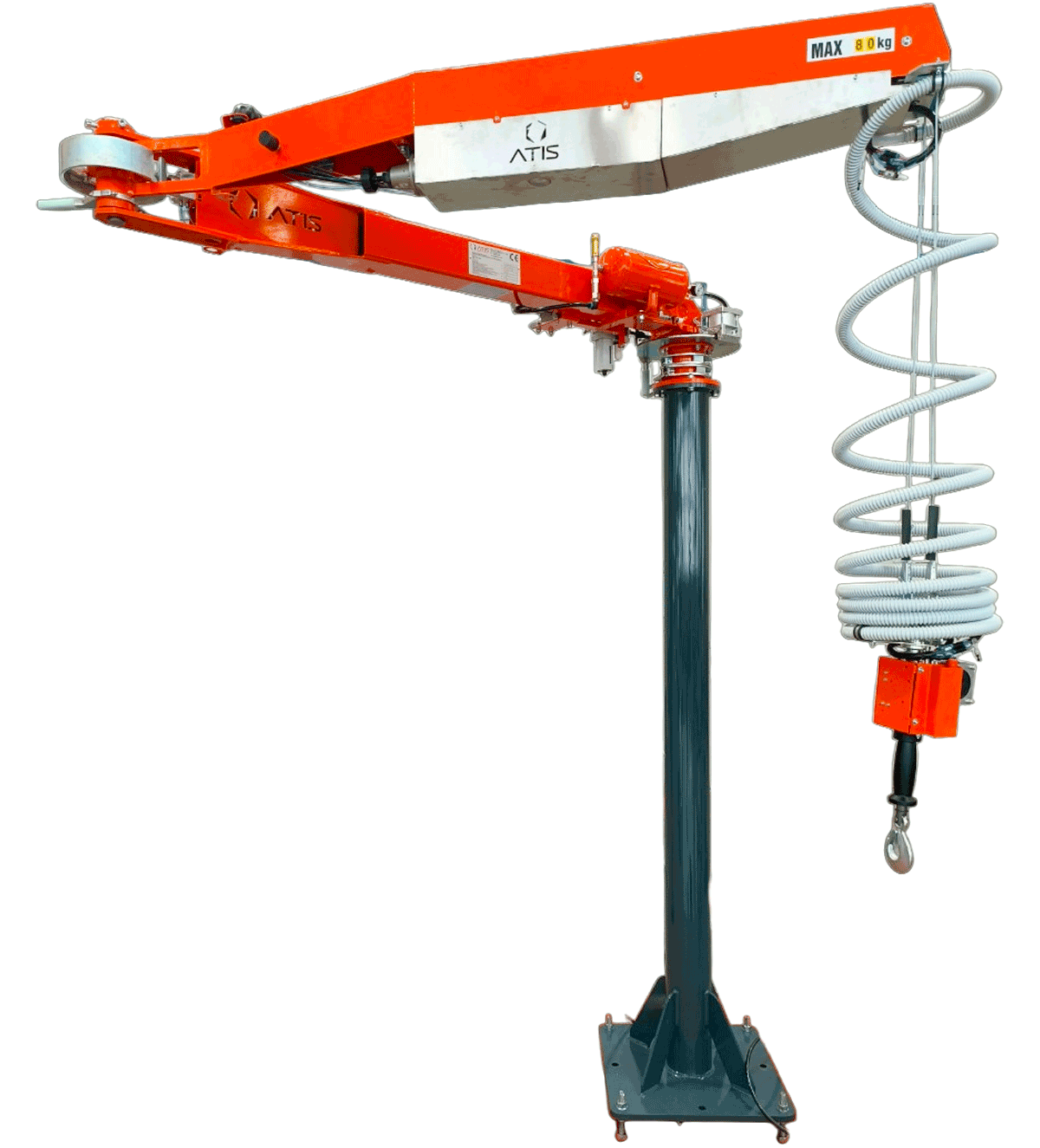

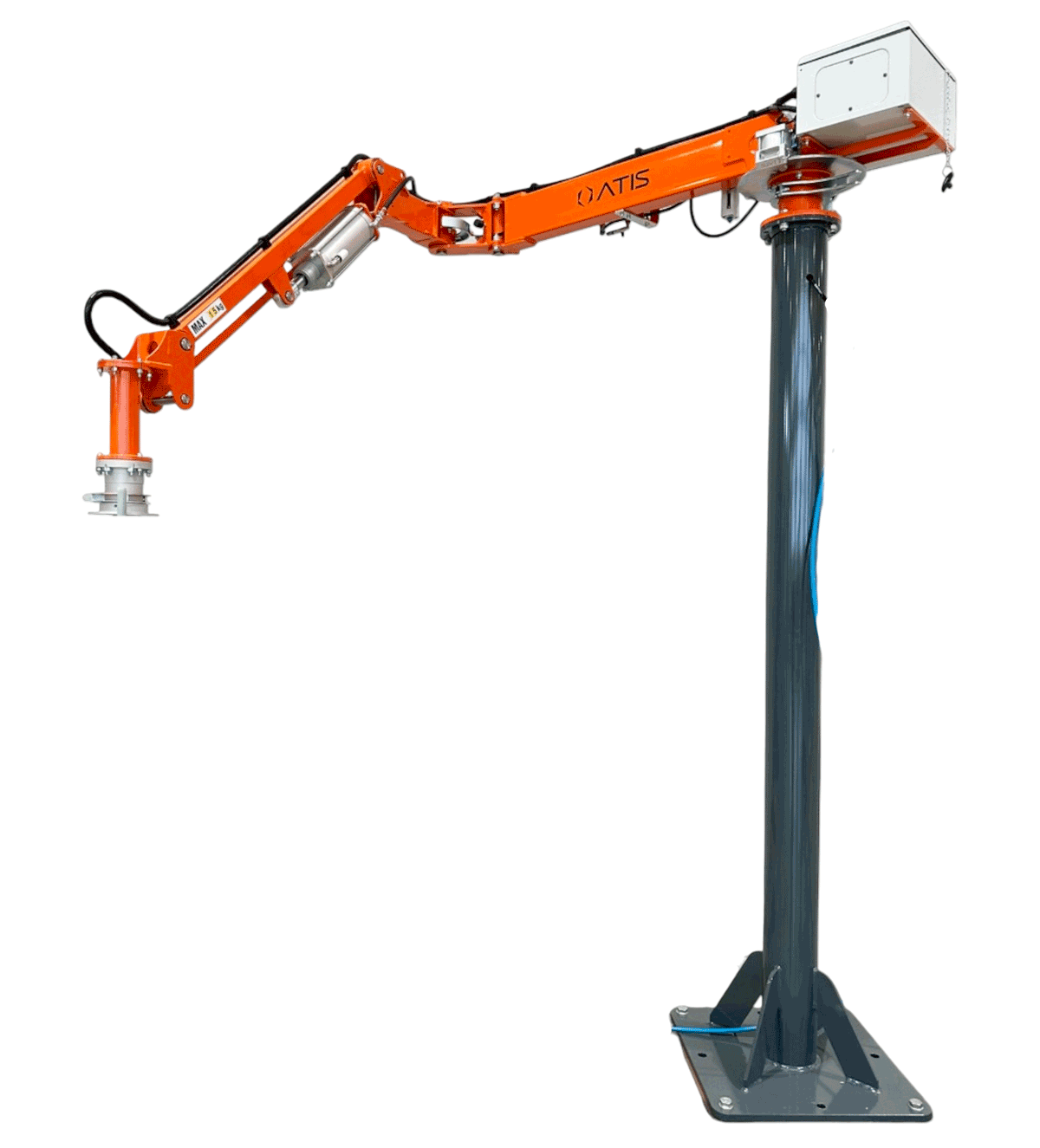

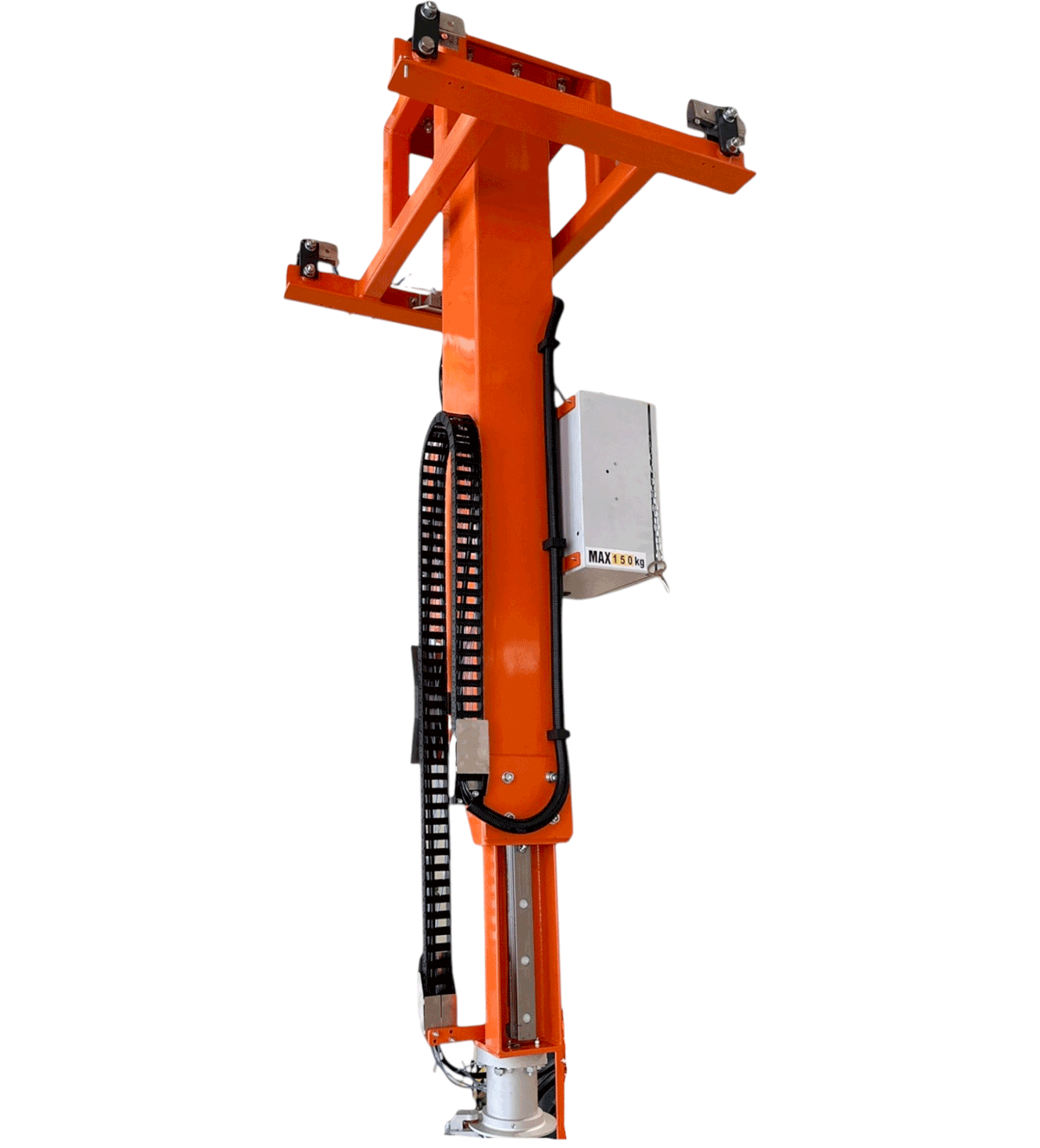

ATIS Industrial Manipulators: ergonomic load handling, safe and effortless

ATIS designs and manufactures industrial manipulators, lifters, and ergonomic load‑handling systems. It makes lifting precise, safe, and intuitive for every need—from delicate components to heavy and bulky loads. The result? Enhanced production efficiency and protected operators in every sector.

High‑performance lifters and balancers

A leader in zero‑gravity devices and industrial balancers, our solutions:

- Reduce operators’ physical fatigue

- Optimize cycle times

- Prevent injuries and musculoskeletal disorders

- Improve workstation ergonomics

Every ATIS system is robust, reliable, and easily integrated into your automation processes.