In the industrial sector, material handling is a crucial activity, yet often demanding and risky for operators. Hoists and jib cranes have long been used, but industrial manipulators represent a significant evolution, offering major advantages in terms of ergonomics, safety, and efficiency.

This article explores the differences between these solutions and explains why ATIS industrial manipulators stand out on the market.

Contact us now

Fields marked with * are mandatory.

Blog

Industrial Manipulators: The Ergonomic and Efficient Solution for Material Handling

Hoists vs. Industrial Manipulators

Hoists or Jib Cranes

- Hoists, whether electric or manual, are primarily designed for the vertical lifting of loads.

- Horizontal movement is limited and often imprecise, requiring the operator to manually guide and stabilize the load.

- The operator is forced to support part of the load’s weight and perform repetitive, strenuous movements — increasing the risk of musculoskeletal disorders, especially to the back and shoulders.

- They can also create obstacles to the movement of operators and materials.

Industrial Manipulators: 360° Handling and Total Control

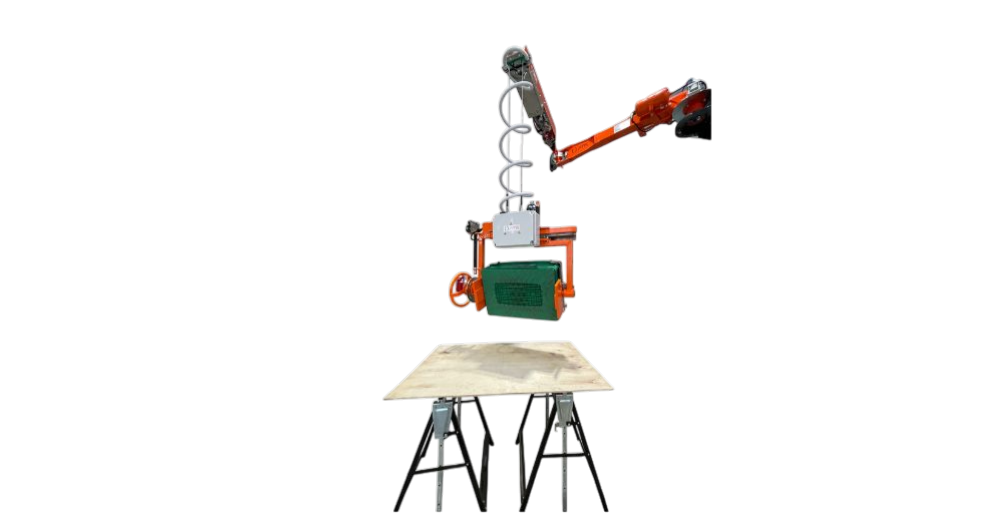

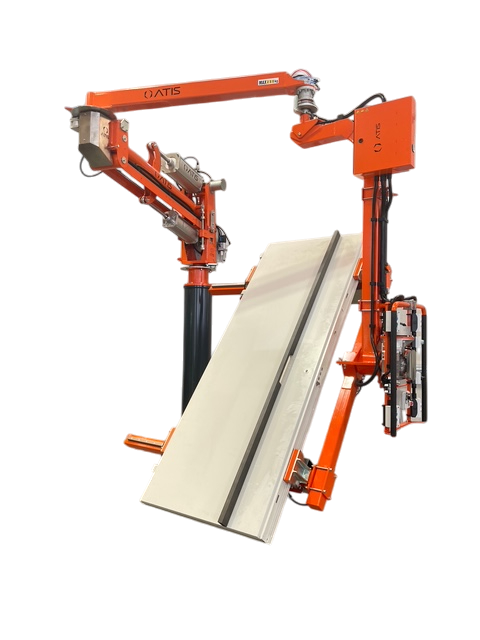

- They allow lifting, lowering, rotating, tilting, and translating loads with minimal effort, completely eliminating the weight of the object being handled.

- Thanks to balancing systems and intuitive interfaces, ATIS industrial manipulators provide precise, micrometric control over load positioning, making complex operations easy.

- These manipulators almost completely eliminate the physical effort required from the operator, drastically reducing the risk of injuries and occupational illnesses.

- They can be fixed or mobile, column mounted or overhead, offering unparalleled flexibility.

- They provide a wide working area and can reach difficult points, including undercut positions.

- The compact, intelligent design of ATIS manipulators allows optimal use of available space, reducing clutter and improving workplace organization.

Why Choose ATIS Industrial Manipulators: the Competitive Advantages

Advanced Ergonomics for Operator Well Being

- ATIS manipulators are designed with a strong focus on ergonomics, minimizing physical effort and preventing operator fatigue.

- Intuitive controls and user friendly interfaces allow the manipulator to be operated naturally and comfortably.

- Reducing the risk of injuries leads to lower absenteeism and contributes to a healthier, more positive workplace environment.

Built In Safety for the Protection of People and Materials

- ATIS manipulators are equipped with state of the art safety devices to prevent accidental load drops and protect operators from potential hazards.

- Locking systems, presence sensors, and acoustic and visual alarms ensure safe and reliable operation.

- The gripping systems are engineered to hold the load securely and stably, preventing damage to the materials being handled.

Versatility and Adaptability for Every Industrial Need

- ATIS manipulators can handle a wide range of materials with different shapes, sizes, and weights.

- The gripping systems can be customized to meet specific customer requirements — using suction cups, clamps, forks, magnets, or other devices.

- ATIS manipulators are used in numerous industrial sectors, including automotive, food processing, pharmaceuticals, logistics, and many more.

Efficiency and Productivity to Optimize Processes

- ATIS manipulators enable faster and more precise material handling compared to traditional solutions, reducing cycle times and increasing productivity.

- Automating certain stages of the handling process frees operators from repetitive and strenuous tasks, allowing them to focus on higher value activities.

- The increase in efficiency results in lower operating costs and improved competitiveness for the company.

Quality, Reliability and Continuous Innovation

- ATIS is a company with solid experience in the industrial handling sector, known for the high quality of its products and the reliability of its service.

- ATIS continuously invests in research and development to offer innovative, cutting edge solutions capable of meeting the increasingly complex needs of the market.

Customized Solutions for the Specific Needs of Each Customer

- ATIS does not simply supply standard products — it designs and manufactures tailor made manipulators to meet each customer’s unique requirements.

- The ATIS technical department works closely with the customer to analyze their needs and develop the most effective and efficient solution.

- After sales support ensures ongoing, qualified assistance for maintenance and optimization of the manipulator.

Conclusion

Industrial manipulators represent a major breakthrough in the field of material handling, offering unmatched advantages over hoists and jib cranes in terms of ergonomics, safety, efficiency, and productivity.

ATIS industrial manipulators – the result of 50 years of study and experience – feature an advanced functional design compared to other market solutions. They deliver superior performance in precision, speed, and ease of use, whether handling light or heavy loads.

This superiority, combined with the quality, versatility, and customization of ATIS solutions, makes them the ideal choice for companies striving for excellence.

Choosing ATIS means investing in the future of your company: protecting operator well being and optimizing production processes to reach new levels of performance.

ATIS industrial manipulators are a strategic investment for companies seeking to improve efficiency, safety, and ergonomics in material handling.

Let’s design your handling solution together.

Safe. Ergonomic. Tailor-made.