But what happens when assisted handling goes beyond simply lifting a weight?

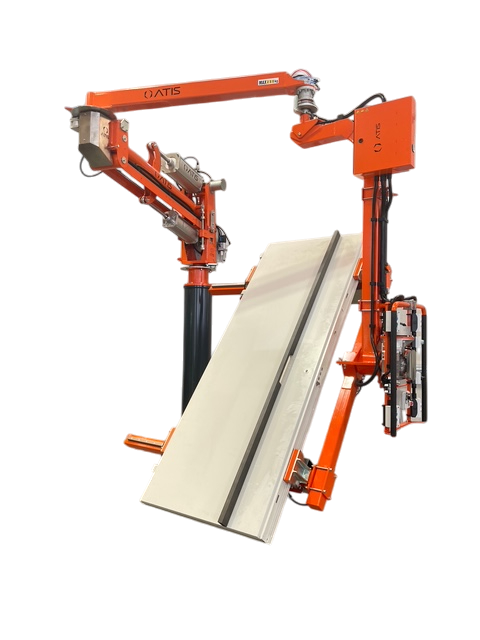

The answer lies in the evolution of ATIS handling manipulators – tools that are redefining the very concept of industrial material handling and transforming operations in dynamic workplaces.

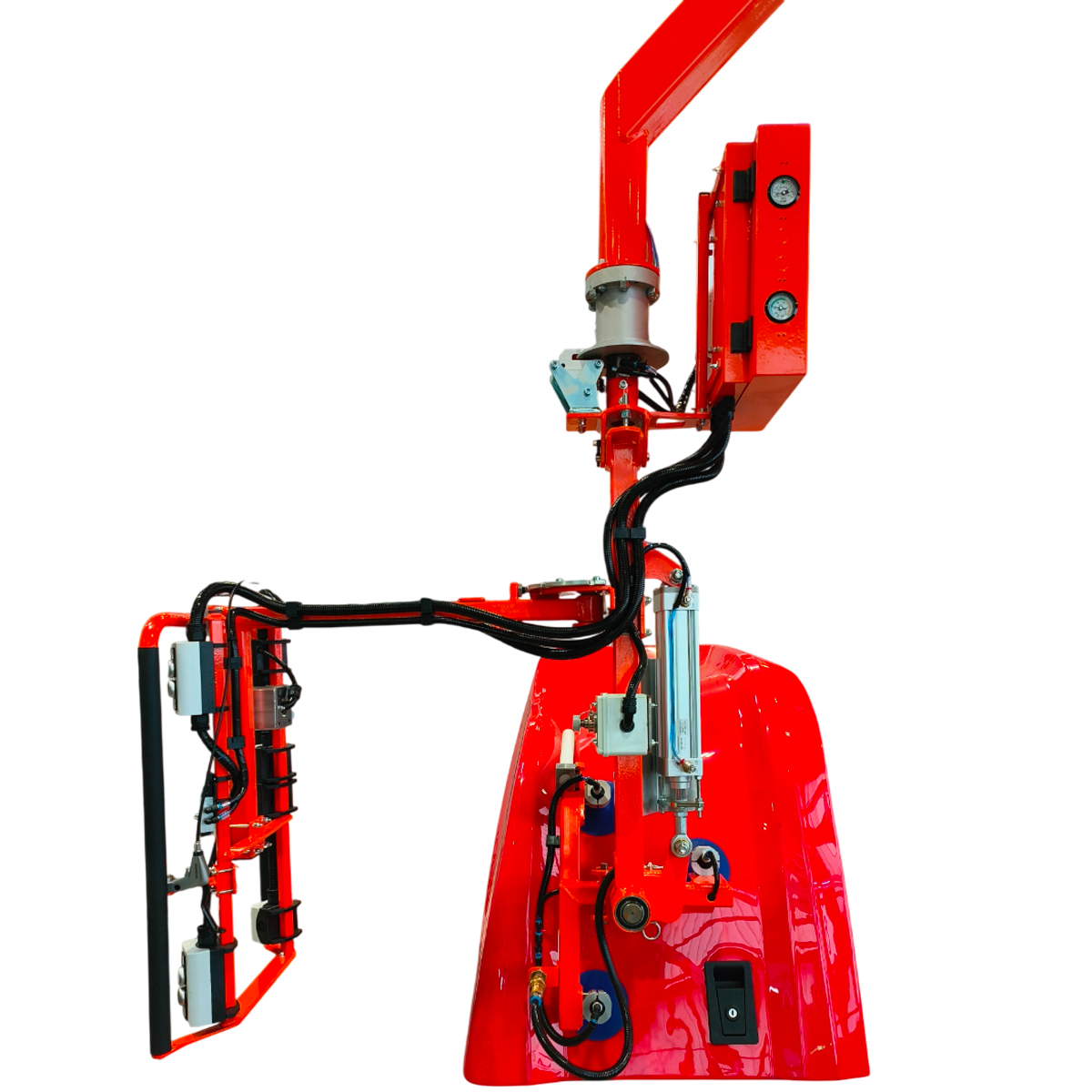

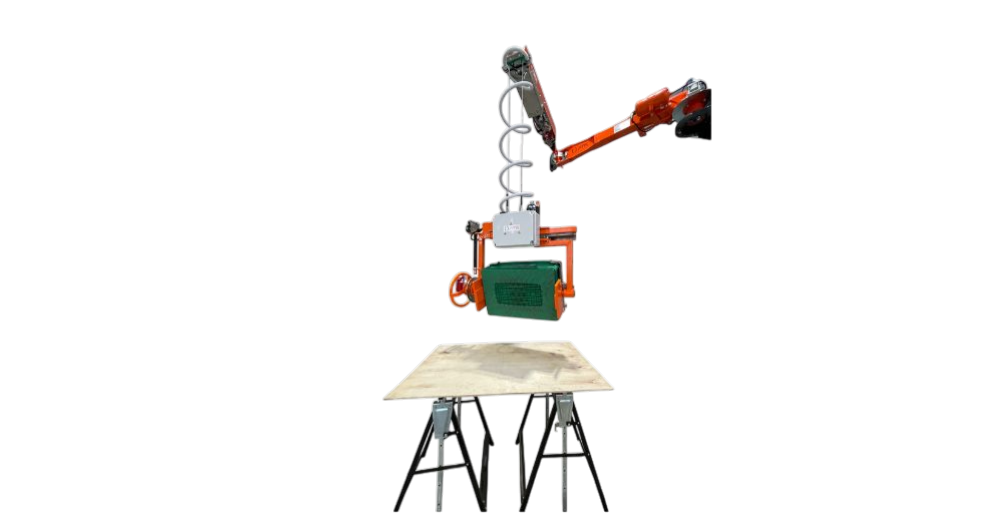

No longer simple “aids” for lifting heavy loads, the latest generation ATIS pneumatic balancer manipulators have become true systems that adapt to the specific needs of both the operator and the production process. Their ability to deliver dynamic ergonomics and flexible efficiency is opening new frontiers in material management.